The infrared drying tunnel (the ‘IR tunnel’) has been designed to meet quality demands for finished product.

The tunnel heats using medium waves infrared lamps that reach the emission levels required in a very short space of time, thereby reducing wait times for starting work, to a minimum.

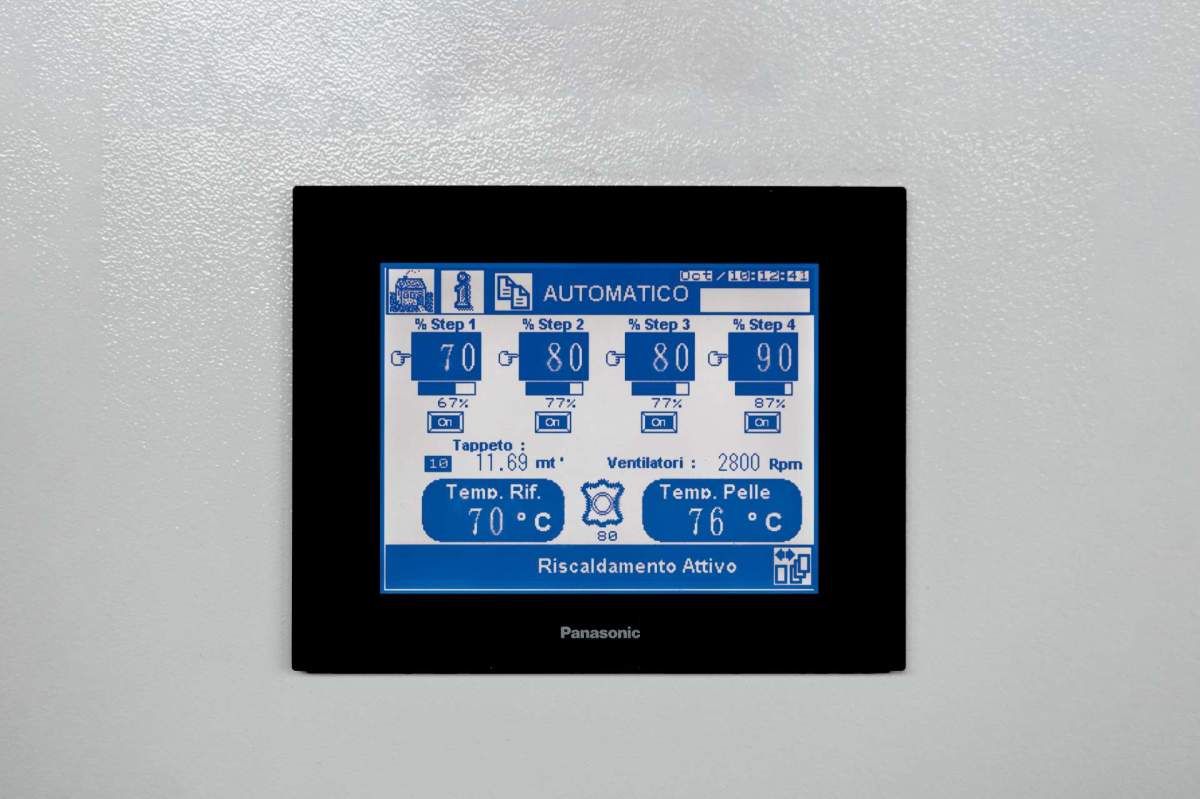

Power is regulated by means of an electronic control system (PLC) with “touch screen” device that guarantees regulation of the radiating power up to 4 drying stages.

The control system monitors in continuous the temperature of the leather coming out from the tunnel, by an optical pyrometer and adjust the power to the lamps.

The possibility of monitoring the surface temperature of the skin also ensures process repeatability levels at any time of the year.

A considerable saving in terms of used energy is given by the “energy saving” system of power sent to the lamps that automatically modulates to a minimum power.

Another key feature of this tunnel is the possibility of its working even without the internal fan. This reduces the possibility of contaminating leather surfaces with dust.

FEATURES

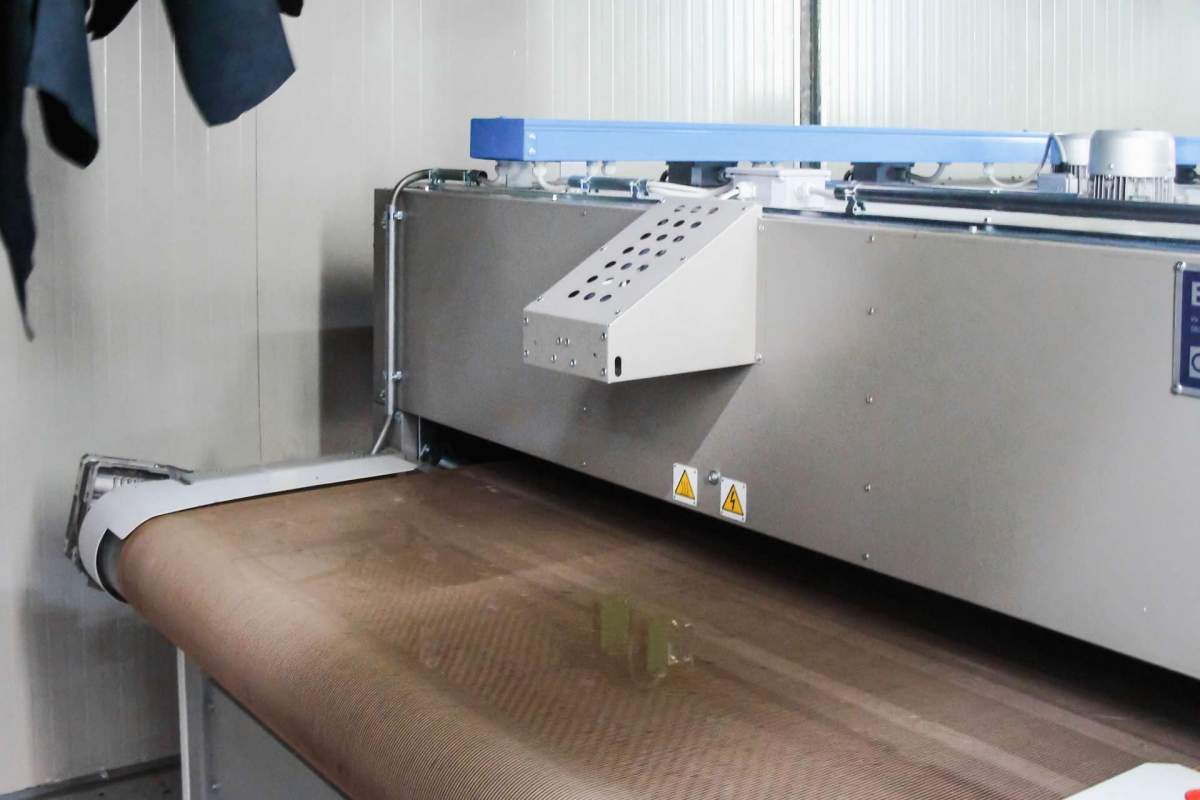

- Structure built entirely from galvanized and pre-painted sheet metal

- Thermal insulation panels with high density and self-extinguishing

- Powered entirely by electricity.

- High specific power.

- PLC system control.

- User control panel with touch screen.

- Saves drying recipes.

- Modular bulb power control by electronic control relay.

- Leather surface temperature shown and controller by electronic pyrometer.

- Leather presence on conveyor belt sensor.

- Built with modular elements.

- Large filter surfaces.

- Series of rollers supporting the belt, positioned at regular intervals.

- Large front and rear hatches to allow for easy internal inspection and maintenance of all parts.

- Hot air recirculation system with electric fans.

- Recycled air with stop option.

- Uniform hot air distribution throughout the surface of the conveyor belt.