The "combined" cleaning system has been designed and built to meet the demands of those using the system in a diversified fashion.

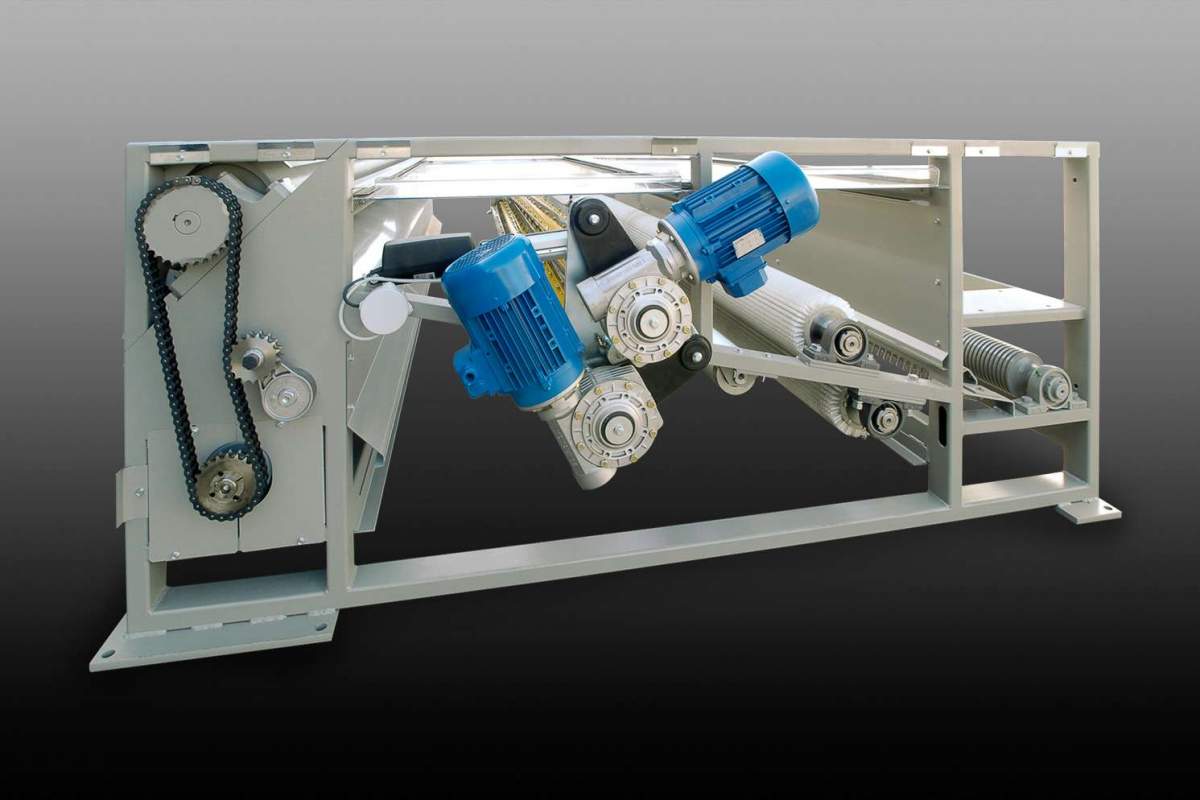

The first stage of cleaning consists of 2 counter-rotating blade roller, each powered by a specific electric gear motor. Each roller consists of 8 stainless steel grooved blades that constantly scrape the conveyor belt.

The working pressure of the rotating blade rollers is managed by means of 2 switch-controlled electrical actuators.

A removable stainless steel tank completes the device, collecting dry cleaning residues.

The brush roll cleaning system is then installed to clean the conveyor belt using 2 counter-rotating rolls covered with nylon brushes, constantly supplied with water.

2 stainless steel toothed blade scrapers follow the brushes. These allow for a more efficient cleaning of the wires.

Movement is carried out by means of an electric motor to rotate the brushes, and pneumatic pistons to activate the scrapers.

A removable stainless steel tank completes the device, collecting water and cleaning residues.