The automatic rotary painting booth model ROT-SL is the result born of the customers’ needs to have a cabin with large front doors to simplify cleaning and new operations ergonomic arms to minimize the movement of air inside of the cabin, so that it is easier to clean and more difficult to dirty.

Our mission is to satisfy your needs and your expectations with the most advanced product in the world; efficiency and control are our vision for a more productive and greener future. Quality, productivity and reproducibility are the fundamental points of the technological development of the new rotary spray booth; the result of in-depth studies on the control of the air flows inside the booth and on the savings of the chemical, water and energy.

This project has been matured with a synergy of skills, our 50-year know-how in the tanning sector and in the specific implementation of over 4000 automatic spraying systems combined with your experience and knowledge in use that has shown us the right path to turn a dream into reality.

Available in 12 models (from 1500 till 3400) in ratio version 1,2 or 1,41 with the possibility of installing up to 3 guns per arm with separate paint supply circuits,available with total control in real-time of all the parameters on board the machine and remotely, prepared for every type of set-up and configuration of the spraying equipment, the only limit is imagination.

FEATURES

- Structure entirely built from stainless steel.

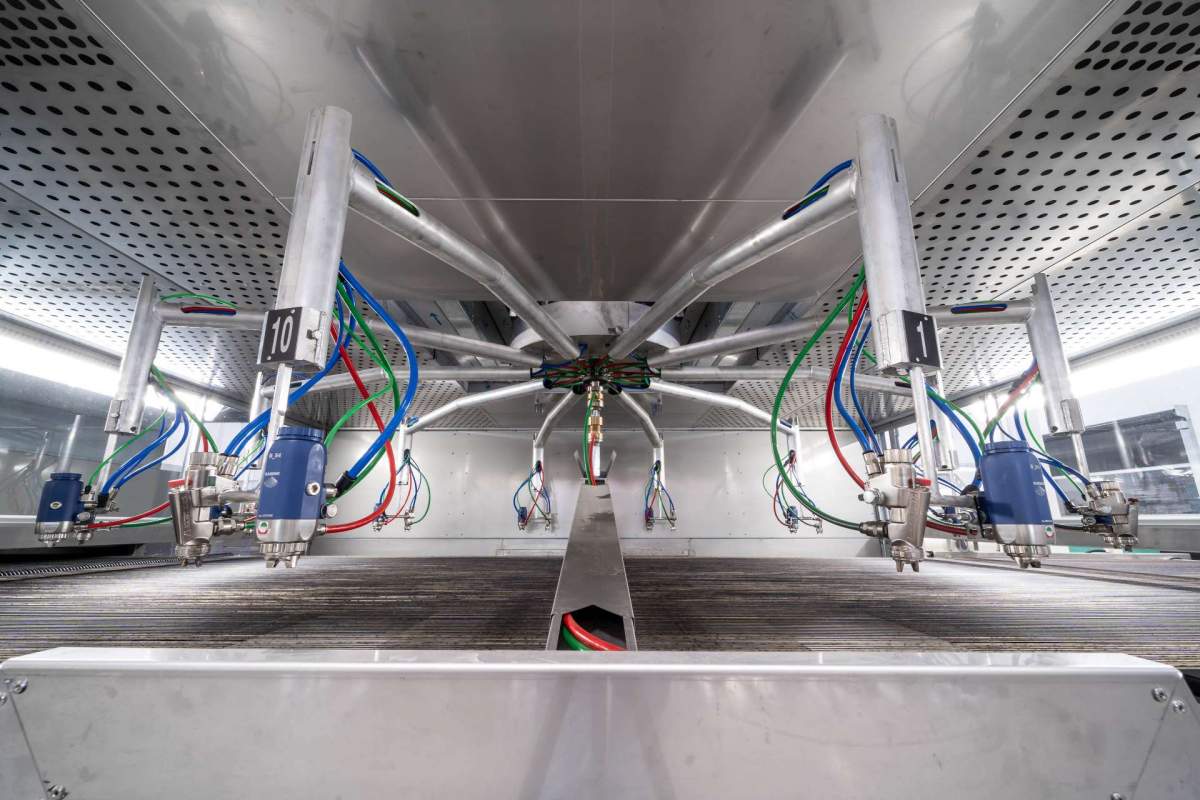

- Strong structure complete with perforated top skies designed to optimize the air flow necessary for proper suction.

- Front sliding doors with aluminum profile of maximum size for complete opening to facilitate cleaning, maintenance and the monitoring of the spraying process.

- Uniform and optimal distribution of the air.

- Internal structures, fed by the spray aerosol, are constantly kept washed through recirculating water veils (or dry filtering when requested).

- Direct air regulation and atomization air unit with digital display in ergonomic position or directly managed by the 15 “Touch Screen of the SprayStation economizer.

- Control unit located on the front of the cab with vision and control in optimal position.

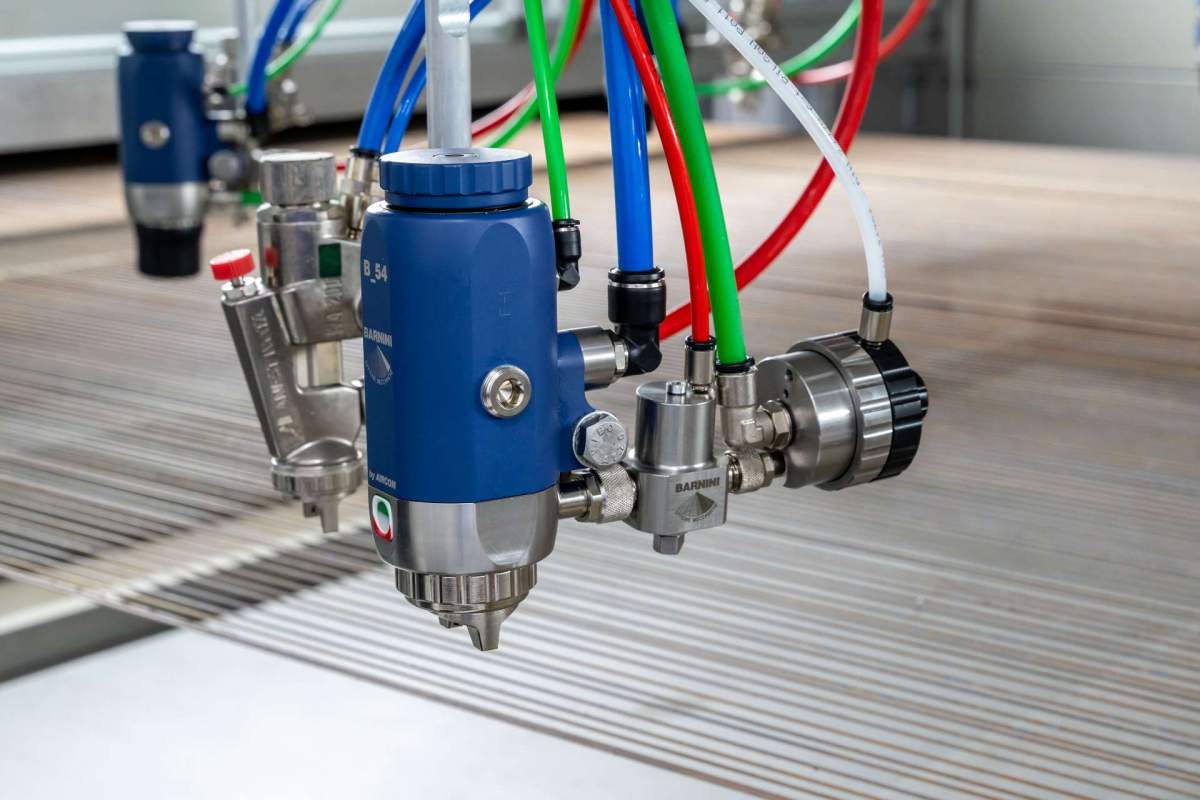

- Rotary distribution unit designed for any spraying equipment (conventional, airless, airmix, HVLP, LVLP). Predisposition for low pressure spraying system with precise regulation for air atomization with working pressures up to 0.2 bar.

- Rotary distribution unit with the possibility to mount the paint distributor in the upper and external part of the cabin or in the lower part, inside the spray booth, according to the application requirements.

- Carousel with minimal design to reduce internal cleaning times thanks to the concept of the new oval arms.

- Ring or centralized (direct) paint distribution.

- The paint distribution circuit provides, on all models, the possibility of product recovery and circuit cleaning in a short time by pumps. The product still present in the circuits when the processing has come to an end is recovered with a consequent decrease in the pollutant load and dispersion in the cabin and consequent decrease in production costs.

- Last generation spraying control system complete with transport encoder, carrousel encoder, scan bar up to 5 mm pitch.

OPTIONS

- Air control system that offers the option of direct inlet of filtered and conditioned air inside of the spray booth, taking it directly from outside of the finishing room. The advantages of this system are: air is filtered before entry into the spray booth, conditioning of air entering the spray booth, reduced pressure in the finishing room, reduced overspray during spraying, reduced environmental impact with in an improved microclimate in the workplace.

- Paint distributor up to 10 color circuits made of stainless steel with chrome or ceramic surface treatment on request.

- Chemical flow regulators to ensure homogeneity of product entering the guns.

- Universal quick flush to speed up the washing phase of the color circuit.

- Automatic sprayguns height adjustment system with further direct adjustment on the gun support rod

- innovative spray guns B_54 by high paint transfer efficiency for reduction of overspray resulting in reduced pollution load and saving cleaning time inside the cabin.

- Multifunction system integrated into the “4Flix” arm for automatic cliks adjustment, “Quick Flush” chemical product flushing, air / paint hoses inside of the gun holder arm, quick release of the gun. System available only for the innovative spray gun “B_54”.

- Quick color change system “Fast Change” for the charge, recovery and automatic washing of the color circuit in remote during the spraying phase.

- Complete plant “Control System” with package 4.0 for saving, storing and recalling work recipes (all parameters including drying phase).

- “Energy Saving” system for energy saving and speed control of each motor by inverter.